Our plants are equipped with plasma and ion sources of different types and purposes. In addition to our sources, plants can be equipped with other types of sources – development of our partners.

Our standard plasma sources.

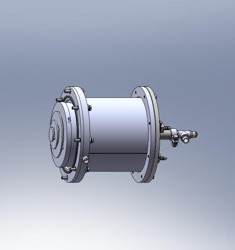

Source of separated gas-metal plasma SPS-1 (Separated Plasma Source).

Direct flow plasma source (evaporator).

Electric arc source with two stage discharge.

Source of metal high energy ions (implanter).

Source of separated gas-metal plasma SPS-1 (Separated Plasma Source).

Source of separated gas-metal plasma purified from micro-particles and neutral components. It is designed for high-quality nanostructured materials and coatings, nano- and microsystems, ion surface treatment and other processes. Read more.

Direct flow plasma source (evaporator).

Direct flow metal plasma source (evaporator). It is widely used to produce solid, wear resistant, corrosion-resistant and decorative coatings for cutting tools and other products. The disadvantage is the presence of particulate material of the cathode in plasma flow and low degree of ionization of gas component of plasma. Read more.

Electric arc source with two stage discharge.

Source with two-stage vacuum-arc discharge provides highly ionized gas plasma in large volumes. It is used for ion surface treatment – ion etching and ion surface cleaning, surface azotizing and creation of other near-surface diffusion layers and other processes.

Source of metal high energy ions (implanter).

Source of metal high energy (up to 100 keV) ions – implanter is designed for ion implantation processes – doping of metal surfaces to change physical and chemical properties (high hardness, wear resistance, corrosion resistance, etc.) and complex processes – coating with a simultaneous bombardment of high-energy ions (doping and ion mixing). Read more.