Plasma equipment and technologies of coatings deposition |

|

|

PLASMA SOURCES Source of separated gas-metal plasma

|

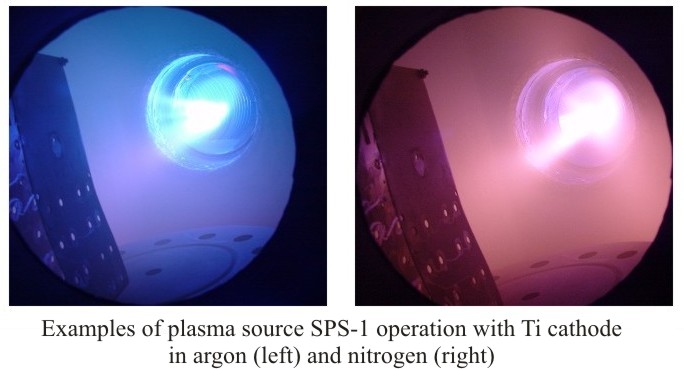

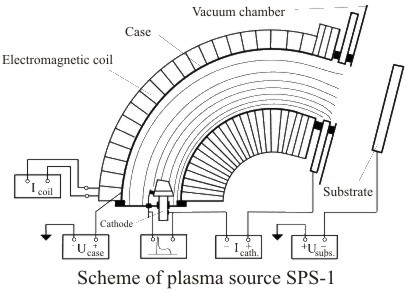

Source of separated gas-metal plasma SPS-1.Cathodic Arc source with separation of the plasma flow SPS-1 (Separated Plasma Source) leads to a new direction in the vacuum electric arc technology. Source not only produces a qualitatively new coating in conventional area of plasma electric arc method – application of strengthening and other functional coatings on tools and machine parts, but opens up the possibility of obtaining coatings and materials for such industries as electronics, MEMS – microelectromechanical systems and other microsystems, creating new functional nanostructure materials and nanosystems with high-performance electric arc method. Here are the scheme of the source, source photos with closed and open cathode unit and source operation examples in argon and nitrogen.

Electric arc source with separation of plasma flow SPS-1 forms gas-metal plasma beam purified from micro- and neutral particles with a high degree of ionization of both metal and gas components. Source allows to control the ratio of components (gas and metal) in the plasma flow. The following table shows the main operational characteristics of the source. For comparison, the right side of the table shows the performance of conventional direct flow plasma source – the evaporator – of plant NNV-6.6.

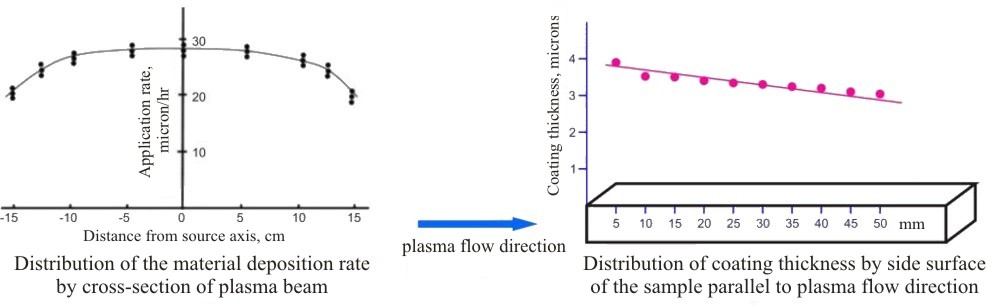

The figure below shows: to the left – distribution of the material deposition rate by cross-section of plasma beam on the substrate, located at a distance of 160 mm from the output of plasma source; to the right – distribution of coating thickness by depth – along side surface parallel to direction of plasma flow. With uniformity of up to 20%, diameter of the "spot" of coating application is 300 mm, and the depth is 50 mm.

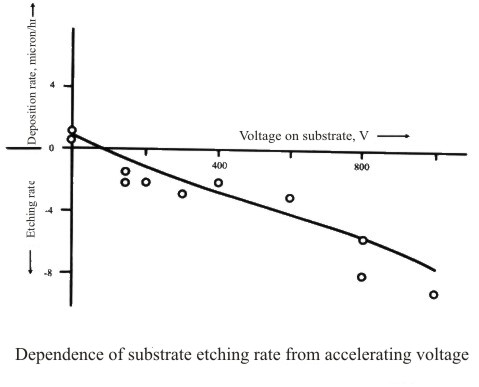

The figure below shows the dependence of substrate etching rate of steel 3 from accelerating voltage when the source is operating in the mode of argon gas plasma – “off” for metal ions.

Materials and coatings made with SPS-1 source have uniform structure and “smooth” surface without damaging by droplets and microparticles. Read more about the structure of our materials and coating surface morphology. Read about the properties and characteristics of coatings and materials made with SPS-1 source.. Features and capabilities of technologies of making materials and coatings with SPS-1 source are sets out on "Technologies page". Electric arc source with separation of plasma flow SPS-1 is a fundamentally new opportunity for plasma electric arc method, not only in traditional areas of application, but also in the field of functional coatings in microelectronics, development of new functional nanostructured materials and nano-systems and other areas. |

_e.jpg)