Materials and coatings produced by application from separated electric arc plasma (CALT SID) have a unique set of features and characteristics. CALT SID materials and coatings have:

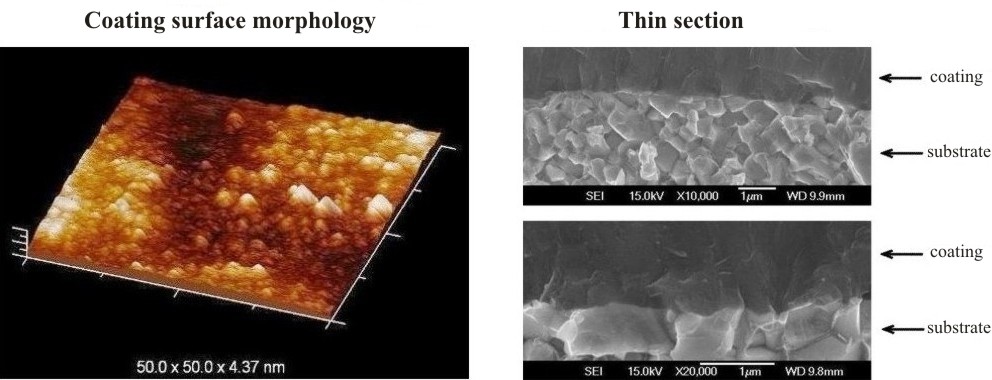

The photographs below show the surface morphology of our coating and the structure of a cross section of the coating on a substrate of hard alloy. Find more about the structure of coating.

The following table shows some characteristics of our coatings of titanium nitride. For comparison, the right column shows similar characteristics for the coatings obtained by conventional direct-flow plasma sources – evaporators. Parameters of our coatings are much greater than corresponding parameters of traditional coatings.

|

№ |

Name |

SPS-1 source |

Conventional evaporator |

|

1 2 3 4 5 6 |

Microroughnesses size, microns Size of dispersed columnar

Microhardness, hPa Palmquist viscosity, n/m Residual stress, MPa Coating continuity |

<0,01 (virtually is the same as

35-37 150 -3000--3500 virtually has no pores |

>0,5 (up to several microns) 1,0-2,0 (up to 5) 25 25 -1700 has pores and inclusions |

For hardening coatings, such features provide:

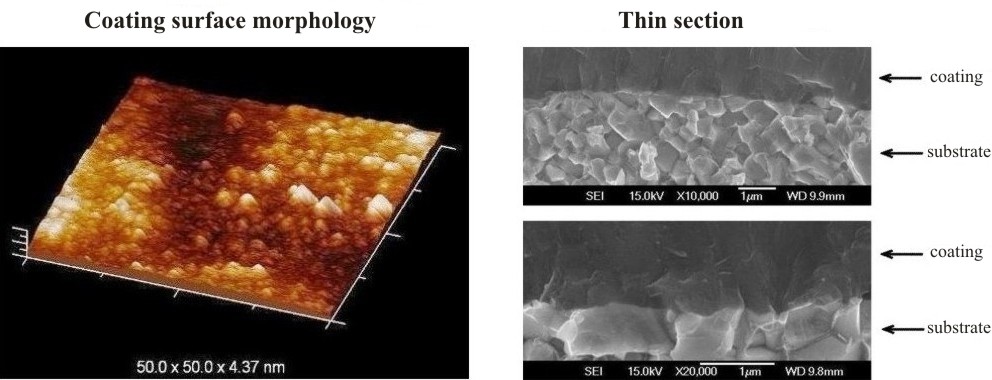

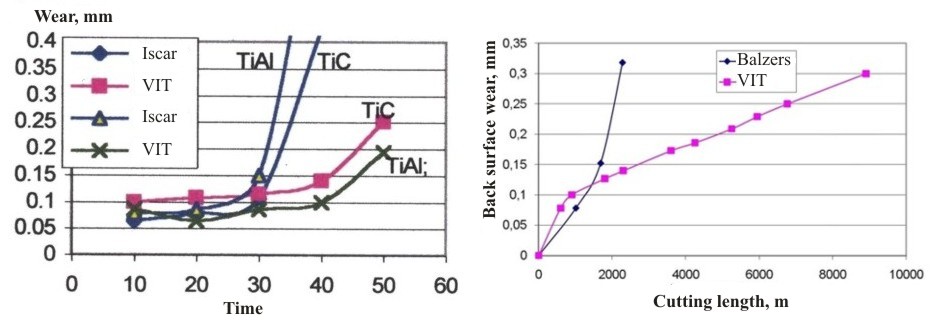

The charts below show the results of tests of hard-alloy cutting blades with our coatings and corresponding coatings of leading respective companies Iscar (Israel) and Balzers (Germany). The left chart shows comparative results with Iscar coatings. Tests were conducted in Iscar laboratories. The right chart shows comparative results of tests of hard alloy plates coated with TiAlN at high cutting speeds (our coating and Balzers coating). Tests were conducted in McMaster University (Canada). Resistance of plates with our coating in both cases is higher. Under severe processing modes (at high cutting speeds) CALT SID coating resistance is several times higher than durability of conventional coatings.

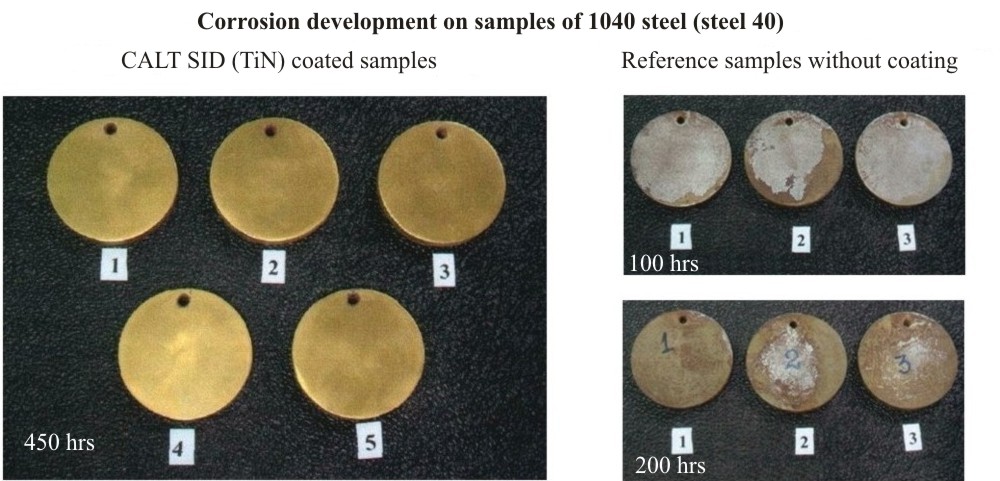

Below the photographs show the results of corrosion tests of samples coated with CALT SID – to the left, and reference samples without coating – to the right. Tests were conducted on Pigmentan Ltd. equipment (Israel) in a climate chamber in humid mist containing 5% of NaCl. Exposure times are indicated in the photographs. Coated samples showed no corrosion even after 450 hours of exposure. Reference samples showed strong corrosion after exposure for 100 hours.

CALT SID coatings is a new class of coatings obtained by vacuum electric arc method. Nanostructured CALT SID coatings have unique properties and functional characteristics.