Plasma equipment and technologies of coatings deposition |

|

|

OUR PATENTS |

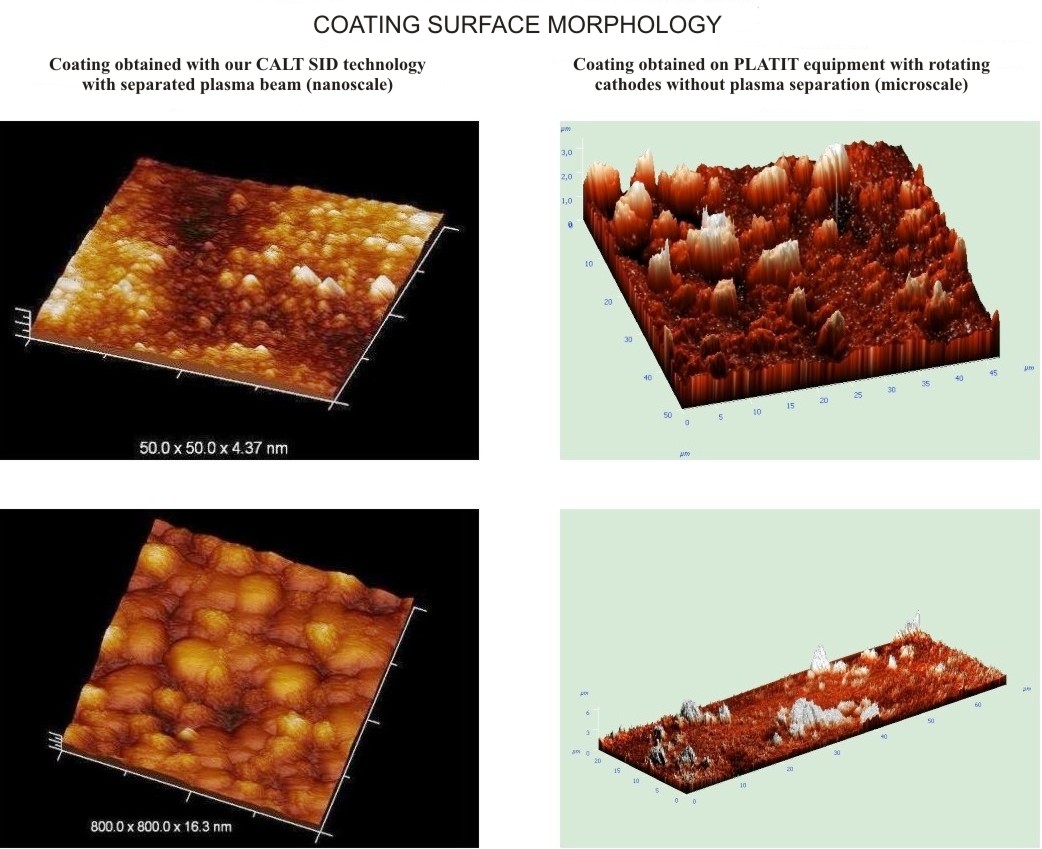

Structure of CALT SID coatingsOur CALT SID coatings obtained from separated plasma have a uniform structure without inclusion of micro-particles and damages to the coating surface as well as in the bulk of material. The first figure shows images of the surfaces of our coatings and PLATIT company coatings, obtained with a scanning tunneling microscope. (Research conducted at the Center for Nanotechnology, nano- and microsystem technology in Bauman MSTU). Our coatings are shown in a nanoscale, PLATIT coating – in microscale. It is seen that roughness value of on the surface of our coating does not exceed 10-20 nm (hundredths of a micron), whereas for PLATIT coatings, roughness value reaches 3-5 microns. PLATIT coating damages are due to the microparticles present in the electric arc plasma. It should be noted that PLATIT coatings have relatively small number of damage – PLATIT equipment has a special system with rotating cathode to reduce the number of microparticles in the flow of electric arc plasma. (See typical damage to the coating by microparticles of cathode material).

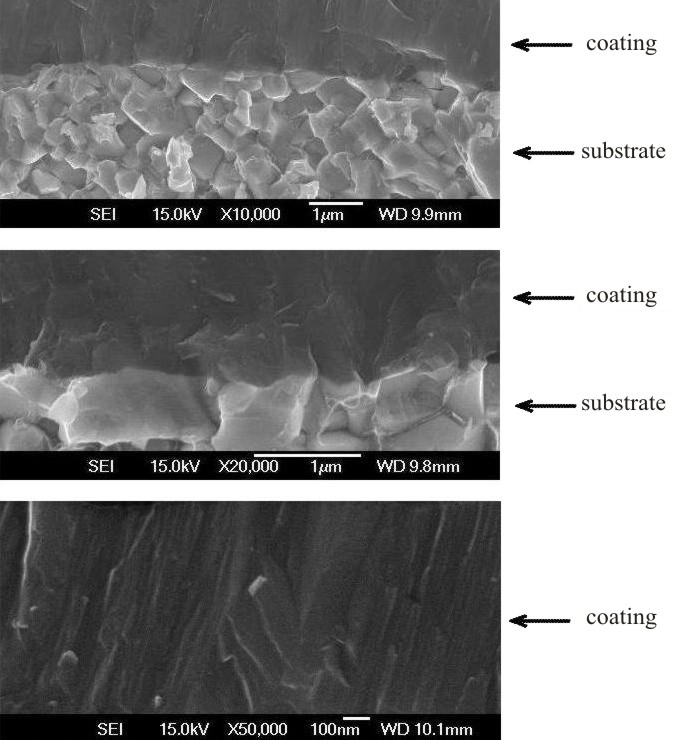

FIG.1 Figure 2 shows electron micrographs of cross section (thin section) of our coating on a substrate of hard alloy. It is seen that the coating is uniform – there are no micro-inclusions and damages inside coating and on substrate-coating boundary.

FIG.2 Here you can find some specifications of our coatings. Possibility to create a uniform structure allows to obtain multicomponent multilayer homogeneous nanostructured materials and coatings. Our technology CALT SID not only made it possible to obtain qualitatively new coatings in traditional area of electric arc method – deposition of strengthening coatings on tools, but also to extend the possibility of highly efficient electric-arc method in such areas as engineering, electronics, MEMS – microelectromechanical systems and other microsystems, creation of new functional nano-structured materials and nanosystems. |