Plasma equipment and technologies of coatings deposition |

|

|

NEW DEVELOPMENT Plant for applying thick protective coatings on large products with complex shape.

Ceramic-like nanostructured materials and coatings based on Al2O3,(sapphire).

Diffusion barriers and contact layers. .

Nanoscale carbon and diamond-like coatings (DLC).

|

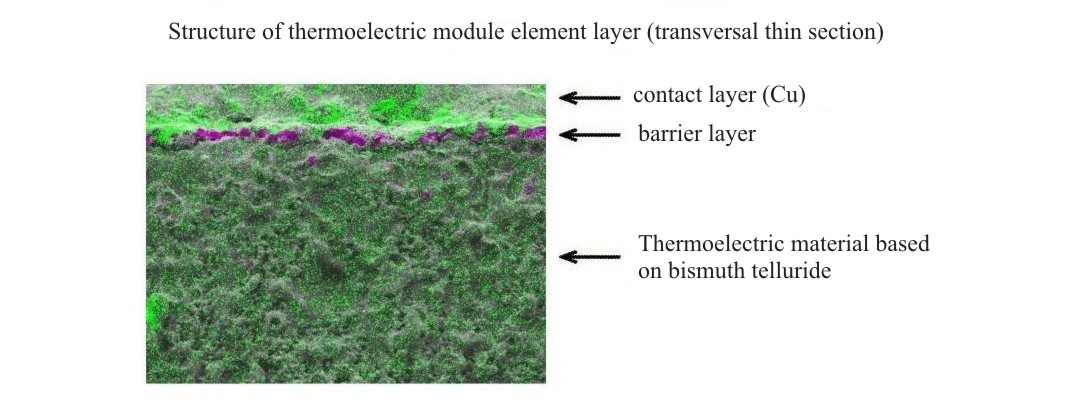

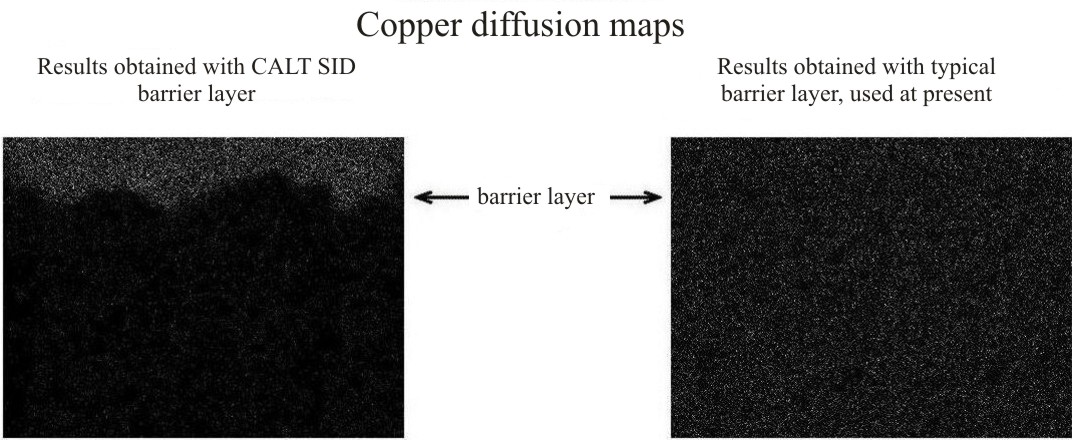

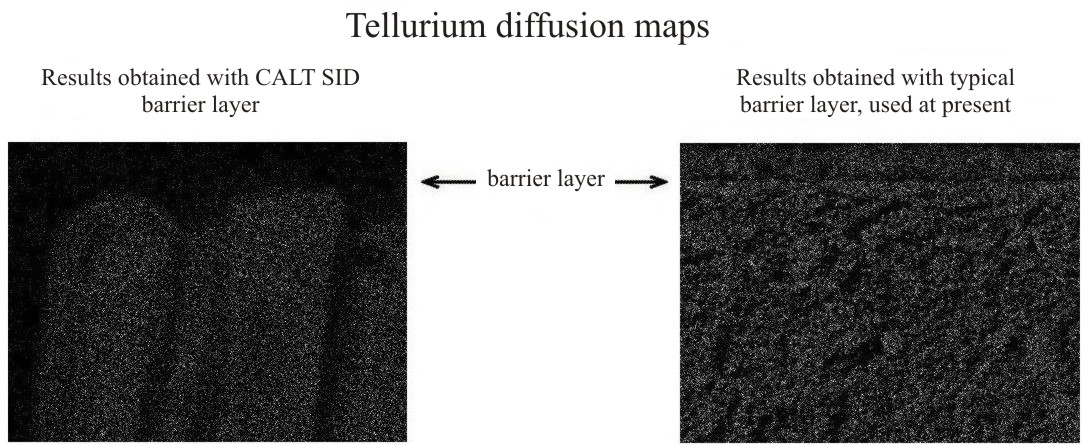

Diffusion barriers and contact layersOperation life of many microelectronic devices is limited to processes of interdiffusion of atoms of different elements in the areas of contact of dissimilar materials. To prevent interdiffusion of atoms and increase operation life of devices, diffusion barrier layers are used that separate various materials at the point of their contact. Effectiveness of barrier layer depends on its structure, grain size, etc. Our technology CALT SID provides high-efficient barrier layers. In particular, barrier coating is developed for thermoelectric modules based on bismuth telluride (Bi2Te3), preventing interdiffusion of copper atoms in thermoelectric material and thermoelectric material atoms in copper electrode at the point of their contact. Development is carried out in cooperation with the Center for nanotechnology, nano- and microsystem technology of Bauman MSTU (Director – V.M. Bashkov, Head of the laboratory – S.A. Belyaeva). The figures show diffusion maps of copper and tellurium over the cross section (microsection) of the element of thermoelectric module for barrier layers produced according to CALT SID technology, and standard barrier layers used in the present. Diffusion maps were obtained after annealing of thermoelectric modules for 5 hours at 250 0C. Concentration of white dots in the figures refers to concentration of corresponding element. High efficiency of CALT SID barrier layer is evident compared with typical barrier layer used in the present. For these annealing conditions, interdiffusion of copper atoms and atoms of thermoelectric material is virtually" stopped" with CALT SID barrier layer. Rough boundary between thermoelectric material and copper contact layer in case of CALT SID barrier layer is due to initial shape of bismuth telluride surface.

|